We are still waiting eagerly for our products to show up on the 37th season of the PBS show This Old House. Here is this week’s recap.

Bricklaying Lesson

This week, Nick Deldon, homeowner of the Arlington, Massachusetts project house, got a lesson in laying brick. Mark McCullough, a bricklayer and stone mason, showed Nick how to stick the bricks together with mortar. The mortar should be the consistency of oatmeal, he said. Since evenness is paramount in bricklaying, McCullough used his level both lengthwise and crosswise on every brick. He expertly wiggled each brick into place with the heel of his hand. “Neatness counts,” McCullough advises, wiping away excess mortar.

Visiting a Brick Factory

Then, to learn more about bricks, host Kevin O’Connor took a field trip to the Stiles & Hart brick factory. This amazing Massachusetts factory has been run by the same family for four generations. The bricks are used throughout New England, including in important buildings on Nantucket and Martha’s Vineyard. “We make 10,000 bricks an hour,” says owner and brick maker Lincoln Andrews.

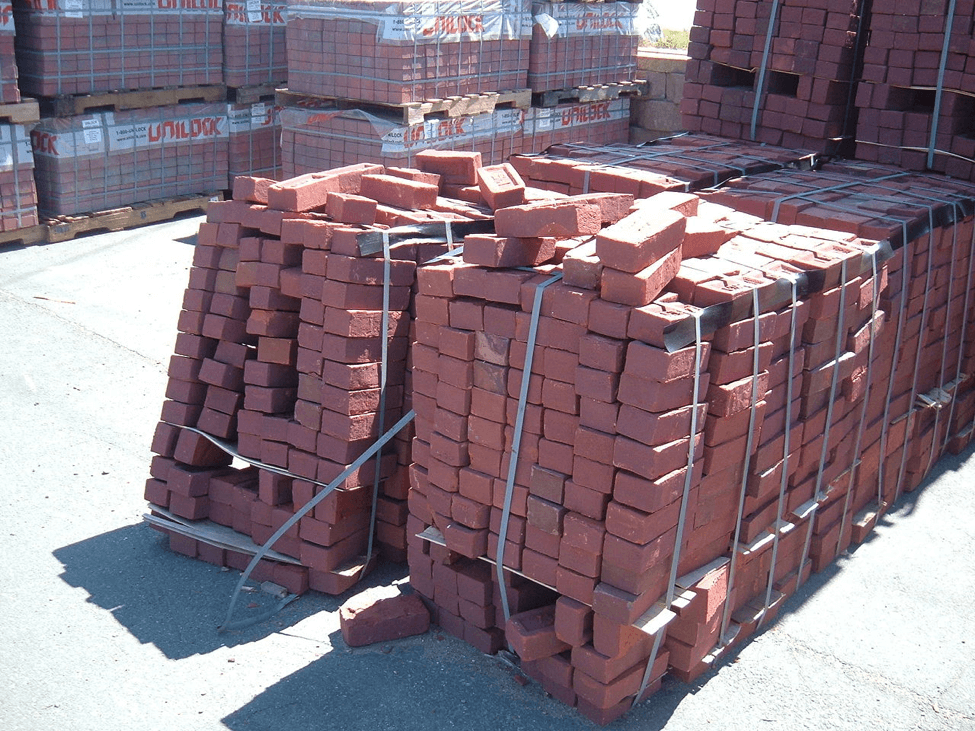

They start with raw, gritty, wet clay, which they blend in a giant mixer called a “pug mill” until it becomes homogenous and smooth. Another machine forms the clay into bricks. But they are still totally wet and unusable at that point. So they spend 22 hours in a 200-degree dryer. During this time, each brick loses a pound of water weight. Then they’re ready for the kiln. Harts & Stiles can fit 85,000 bricks at once into its giant, domed kiln. They crank the heat up to 2,000 degrees for five days. It takes another three days for the bricks to cool down to 120 degrees, a temperature at which they can safely be handled by workers. Then they’re piled into cubes of about 500 bricks and sent to job sites.

https://upload.wikimedia.org/wikipedia/commons/thumb/c/cb/Brick.agr.jpg/1280px-Brick.agr.jpg

Caption: Cubes of bricks, ready to go.

So there you have it, the birth story of a brick.

Kitchen Decor

Kevin is on the road a lot this episode. Next stop, the Bath Ironworks in Bath, Maine. Nick and Emily Deldon meet him there to confer with kitchen designer Heather Krausse. She shows them the plans for the new kitchen, which features a large baking area. The couple enjoys making bread.

Krausse suggests a few different choices for cabinet door styles and wood options. Nick likes a style modeled after the cabinets found in an old ship captain’s house. Their favorite wood is reclaimed Eastern white pine salvaged from a tavern in Maine. It’s been stained a rich brown, but still retains its old nail holes. “We love the patina,” says Emily, a fan of eco and reclaimed building materials

A Steep Pitch

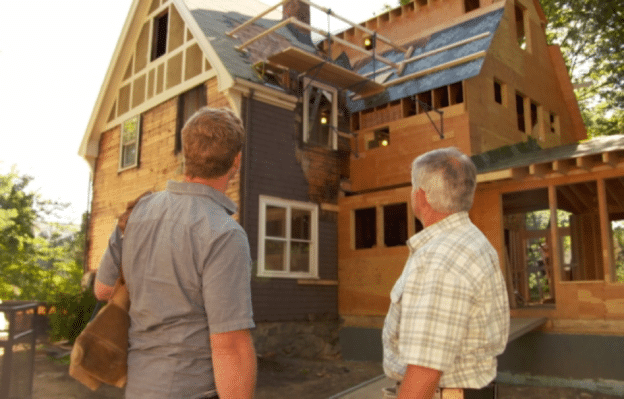

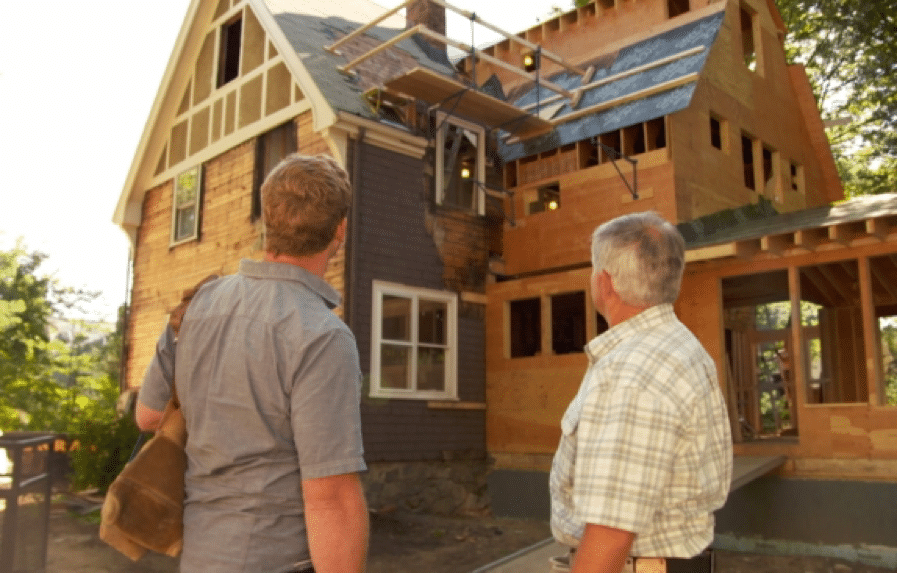

Back on the home front, the old dormers have been torn off the roof line, guilty of not matching the pitch of the main roof. General contractor Tommy Silva shows Kevin how to calculate the correct pitch using an old-fashioned framing square. “Every 12 inches in, we have to go 18 inches high,” says Tommy.

Caption: Kevin and Tommy check out progress on the Arlington project house.

Then he admits that nowadays he plugs variables into his phone’s calculator rather than using the square. Together they frame out the steep new dormers.

And that’s it! Still no fireplace. But the trailer for next week promises they will be building the new chimney. Which is a start.

If your suspense is building and you can’t wait for a new fireplace, call us today! We’d love to help you attain the hearth of your dreams.